Spotlight!

Measuring with precision, keeping Osan ready to fight

haps Magazine Korea December 26, 2023

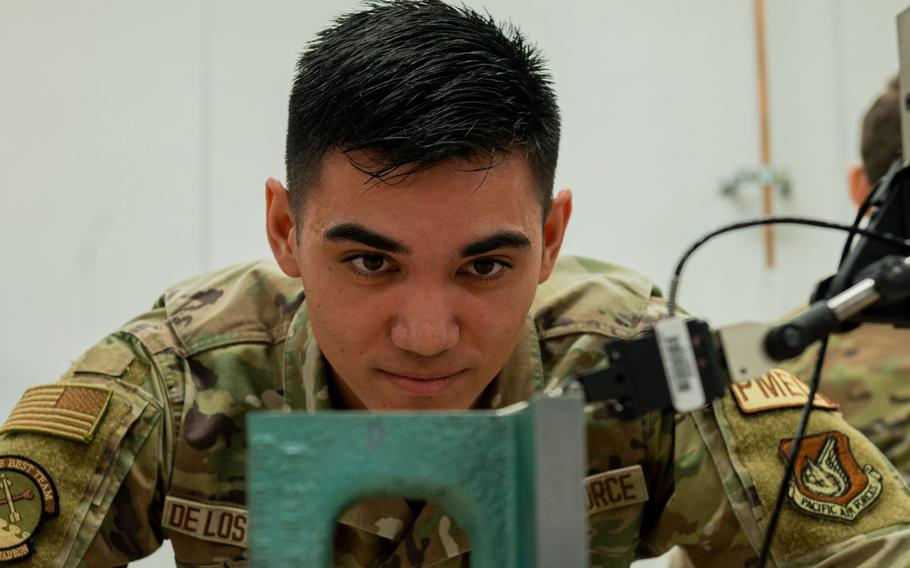

U.S. Air Force Senior Airman Bryant De Los Reyes, 51st Maintenance Squadron precision measurement equipment laboratory logistics technician, compares the parallelism of an angle iron at Osan Air Base, Republic of Korea, Dec. 15, 2023. PMEL plays a fundamental role in keeping Osan’s tools safe, efficient, accurate and reliable. (U.S. Air Force Senior Airman Kaitlin Castillo) ()

OSAN AIR BASE, Republic of Korea -- The 51st Maintenance Squadron precision measurement equipment laboratory plays a fundamental role in keeping Osan’s equipment for many different missions safe, efficient, accurate and reliable.

Almost every piece of equipment in the U.S. Air Force relies on accuracy and precision. Even a slight misalignment in a rifle’s firing pin protrusion gauge can cause a critical discrepancy in the weapon. A miscalibrated torque can crack the paneling of an F-16 Fighting Falcon, generating larger complications in the future.

The 25 personnel assigned are responsible for more than 100 organizations at Osan and across the ROK. This year, the PMEL team calibrated about 4,500 pieces of equipment.

“We assist almost every unit on base,” said Tech. Sgt. Timothy Hetherington, 51 MXS PMEL quality manager. “Our customers range from the maintenance squadron to security forces and the civil engineering squadron.”

Customers who bring in equipment are greeted by USAF Senior Airman Bryant De Los Reyes, 51 MXS PMEL logistics technician. De Los Reyes categorizes equipment by highest priority, allowing crucial items to be calibrated and sent back to the customer in a timely manner.

“There’s always people coming and going at Osan,” said De Los Reyes. “It’s my job to assist people and make sure they’re aware of what equipment needs to be calibrated on time so it doesn’t cause any stoppages on base.”

The PMEL flight calibrates nearly every piece of equipment in every phase of maintenance. This ensures accurate and reliable tools are being used on Osan’s aircraft.

“We work to make sure the equipment we provide is accurate and calibrated,” said Hetherington. “If we’re unable to calibrate torque wrenches, it would risk the safety of our F-16s [Fighting Falcons] during flights.”

The PMEL flight is integral to Osan’s mission and ensures the protection of personnel through precision and reliability.

“We provide safety,” said Hetherington. “We make sure that things are done correctly the first time.”